Hiroshima University researchers developed a laser plus hot‑wire additive method that 3D‑prints WC–Co cemented carbide using pre‑sintered rods rather than powder. Introducing a thin nickel‑based interlayer between the steel substrate and the carbide prevented iron contamination and thermal decomposition, preserving a near‑sintered microstructure. Final deposits achieved surface hardness around 1400 HV, while the technique reduces tungsten and cobalt usage. Remaining challenges include initial cracking and demonstrations of complex geometries.

New 3D‑Printing Method Builds Ultra‑Hard WC–Co Carbide From Sintered Rods and Cuts Material Waste

Researchers at Hiroshima University have demonstrated a laser‑based additive manufacturing method that builds ultra‑hard tungsten‑carbide/cobalt (WC–Co) parts using pre‑sintered rods instead of powder. The approach—combining hot‑wire preheating with a laser and a thin nickel‑based interlayer—produces carbide layers with near‑sintered quality while reducing the amount of expensive tungsten and cobalt required.

Why This Matters

WC–Co cemented carbides are among the hardest, most wear‑resistant materials used for cutting tools and wear parts. Conventional production compacts and sinters powders in large furnaces, a process that consumes large amounts of costly tungsten and cobalt and can be difficult for large or complex geometries. Powder‑based additive methods often introduce porosity, contamination and heat‑induced decomposition that degrades performance.

Process Innovation

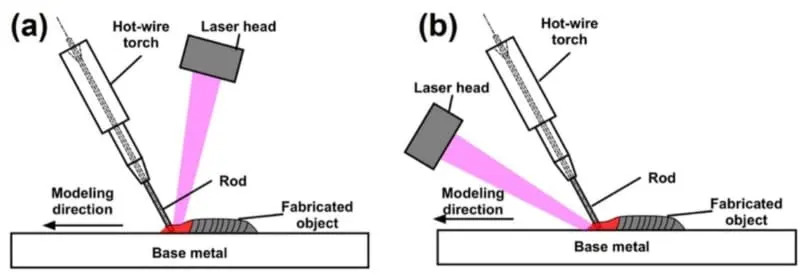

The team, led by Keita Marumoto of the Graduate School of Advanced Science and Engineering, replaced powder feedstocks with solid, pre‑sintered WC–Co rods. They coupled a hot‑wire preheat—which runs current through the rod to warm it—with a laser to soften and deposit material selectively. Preheating reduces required laser power and limits thermal damage, helping preserve the rod's microstructure.

Two Laser Strategies and Their Problems

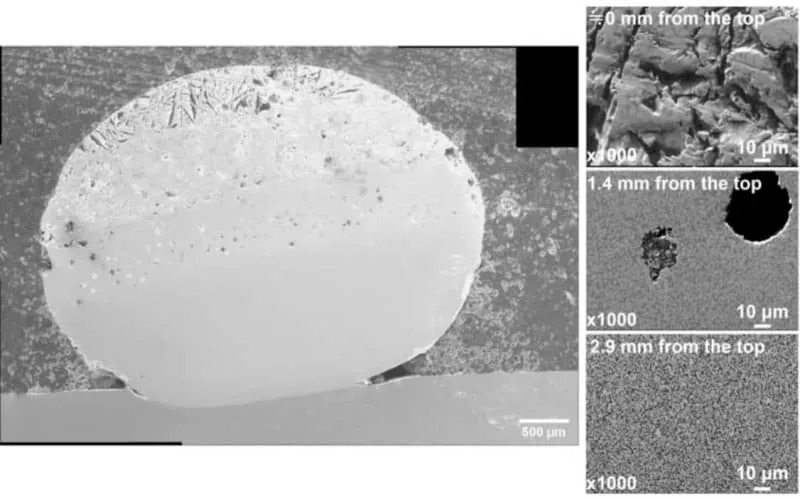

Two laser geometries were tested. When the laser struck the rod directly, upper layers developed porosity, cracks and evidence of carbide decomposition (including graphite formation). When the laser was placed ahead of the rod and focused between the rod tip and the steel substrate, direct chemical breakdown was reduced but iron from the steel migrated into the carbide layer and the cobalt fraction increased, softening the deposit.

Solution: A Nickel‑Based Interlayer

To prevent iron contamination and moderate heat flow, the researchers added a thin nickel‑based alloy layer between the steel substrate and the carbide. This diffusion barrier limited thermal conduction into the base metal and blocked iron migration upward, stabilizing the deposition process.

Results

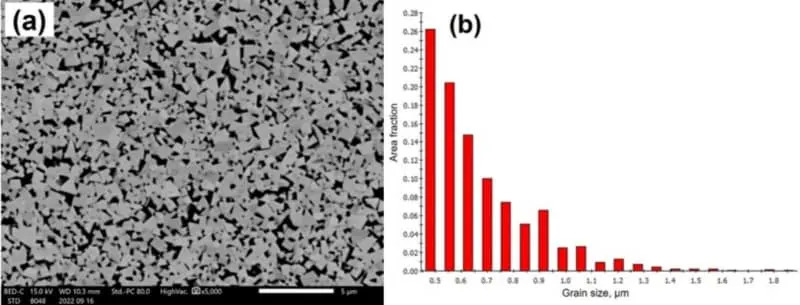

With the nickel interlayer and the hot‑wire preheat, the sintered rod softened for deposition rather than decomposing. Microstructural analysis showed the carbide grains remained small with only modest growth, and the cobalt binder redistributed only slightly compared with earlier trials. Surface hardness reached roughly 1400 HV—placing the deposits among the hardest industrial materials short of sapphire and diamond—while avoiding the pores and deleterious phases seen in powder‑based prints.

“Cemented carbides are extremely hard materials used for cutting tool edges and similar applications, but they are made from very expensive raw materials such as tungsten and cobalt, making reduction of material usage highly desirable. By using additive manufacturing, cemented carbide can be deposited only where it is needed, thereby reducing material consumption,”

Challenges and Future Work

Early build stages still exhibited some cracking; the authors expect improved thermal control during start‑up will reduce this issue. Future work will pursue more complex geometries, alternative substrate and interlayer combinations, and broader validation for industrial tooling. If scaled, the method could enable hybrid tools with hard carbide edges bonded directly to tougher supports and substantially reduce demand for mined tungsten and cobalt.

The full study is available online in the International Journal of Refractory Metals and Hard Materials and is scheduled for the April 2026 print issue.

Help us improve.