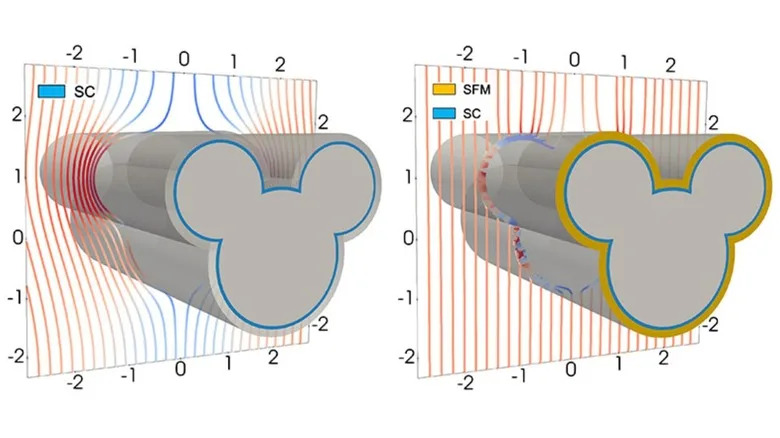

Engineers at the University of Leicester have published a practical production method for magnetic cloaks that can render objects effectively invisible to external magnetic fields. The design uses high-temperature superconducting tape wrapped in a flexible nickel-and-zinc epoxy shell, with the shell composition tuned to control magnetic permeability. Significant challenges remain—manufacturing complexity, directional sensitivity, and the need for cryogenic cooling—but the team plans to build and test a working cloak and expects potential applications in labs, hospitals, and industry.

Magnetic Cloak Breakthrough: Practical Shielding From Magnetic Fields Now Within Reach

Engineers at the University of Leicester have outlined a practical method to make objects effectively invisible to external magnetic fields. Published in Science, the work demonstrates a manufacturable approach to magnetic cloaking that could protect sensitive instruments and electronics from disruptive magnetic interference.

What the Team Proposed

The researchers propose a layered design built around commercially available high-temperature superconducting tape as the cloak's core. That core is wrapped in a flexible outer shell made from a nickel-and-zinc powder mixed with epoxy resin. By varying the nickel-to-zinc ratio in the powder, the team can tune the shell's magnetic permeability to shape how external magnetic fields interact with the covered object.

Why This Matters

Magnetic fields can cause malfunctions in precision instruments, medical devices, and laboratory equipment. Until now, magnetic cloaking has largely remained theoretical or restricted to specific, simple geometries. The Leicester concept is the first to demonstrate a practical, scalable production method intended for real-world objects of complex shapes and for a broad range of field strengths.

Key Limitations and Challenges

The authors are clear about several significant engineering hurdles that remain before a deployable device is available:

- Manufacturing Complexity: Fabricating a flexible, multi-material cloak that conforms to complex geometries is technically demanding.

- Directional Dependence: The cloak’s effectiveness varies with the direction of the incoming magnetic field. If the field rotates or the object's geometry changes, the configuration must be adapted.

- Cryogenic Requirements: Because the design relies on superconducting tape, the protected volume must be kept cold, adding complexity and cost for cooling systems.

Dr. Harold Ruiz, a study co-author, says the work “shows that practical, manufacturable cloaks for complex geometries are within reach, enabling next‑generation shielding solutions for science, medicine, and industry.”

Next Steps and Applications

With the production method validated in research, the team plans to build and field-test a physical cloak. If engineering challenges are solved, magnetic cloaks could see rapid adoption where magnetic protection is critical—scientific laboratories, medical imaging suites, and industrial settings—providing an extra layer of defense for devices sensitive to stray magnetic fields. The authors also suggest their method could lower the cost of magnetic shielding compared with existing techniques.

Bottom line: This development marks a meaningful step toward practical magnetic cloaking, but turning the concept into widely used hardware will require solutions to manufacturing, orientation, and cryogenics challenges.

Help us improve.