A team at Swinburne University developed a fungal recycling method that converts shredded mattress foam into a lightweight, fire-resistant insulation. Using Penicillium chrysogenum, fungal growth binds foam and precipitates calcium carbonate to form a composite that withstood about 1,832 °F (≈1,000 °C) and performed similarly to commercial insulations. With scale-up and further testing, the process could yield fire-resistant insulation, building panels, or parts for 3D-printed construction.

Fungus Converts Old Mattresses Into Fire-Resistant Insulation

Buying a new mattress can be stressful — you expect to sleep on it for years — but disposing of the old one creates a serious environmental problem. Although many mattresses contain more than 75 percent recyclable material, an estimated 50,000 mattresses are discarded every day in the United States, and bulky components can take up to 120 years to decompose in landfill.

A Biological Answer

Researchers at Australia’s Swinburne University of Technology have developed a process that transforms retired mattresses into safe, eco-friendly building insulation. The team used a fungus, Penicillium chrysogenum, to turn shredded polyurethane foam from old mattresses into a lightweight, heat-resistant composite.

How the Process Works

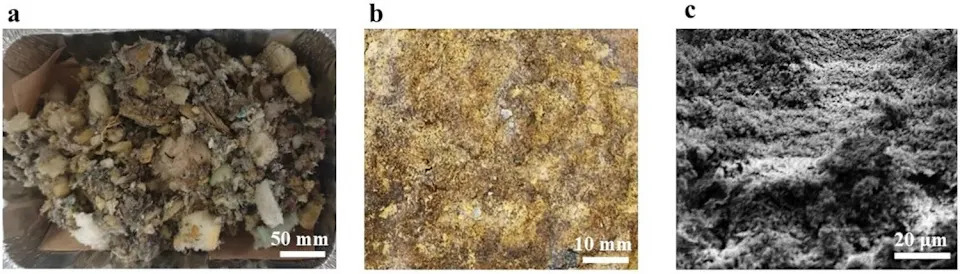

After cultivating spores of P. chrysogenum, the researchers mixed them with shredded mattress foam. As the fungal hyphae grew, they bound foam particles together and induced precipitation of calcium carbonate (a common mineral). Those mineral deposits interlaced with the foam to form a solid composite: light in weight, structurally bonded by fungal growth, and naturally fire resistant.

Although P. chrysogenum is not the exact species Alexander Fleming found (that species is Penicillium rubens), it belongs to the same genus and demonstrates useful biomineralization abilities for this application.

Performance and Potential

In laboratory stress tests the composite withstood temperatures approaching 1,832 °F (about 1,000 °C) and showed insulating performance close to commercial building insulations. "The material performed well as an insulator, with heat-blocking ability very close to commercial insulation products already used in homes and buildings," said study co-author and chemical engineer The Nguyen.

The team envisions further development to scale the method and refine the material for uses such as fire-resistant insulation, building panels, and components for 3D-printed construction. They also note that additional engineering, long-term durability testing, and regulatory review will be needed before commercial deployment.

Why It Matters

"Through natural biological processes, we can give this waste a second life," Nguyen said, highlighting how combining biology with waste materials and manufacturing science can produce low-impact solutions that benefit the environment.

This approach could reduce landfill volume, cut the environmental cost of mattress disposal, and create new sustainable construction materials derived from post-consumer waste.

Help us improve.