Summary: Researchers at Peking University report a carbon-nanotube–reinforced aramid fabric that is about three times stronger than Kevlar, measures 1.8 mm thick, and absorbed 706.1 MJ/m3 in ballistic tests — roughly double the previous record. The team achieved this by aligning treated single-walled carbon nanotubes with polymer chains so the components lock together and resist slippage under impact. Published in Matter, the study highlights strong lab-scale results but notes that scale-up, cost, durability and real-world validation remain necessary steps.

Carbon Nanotube Fabric Beats Kevlar: 3× Stronger, Just 1.8 mm Thick

Scientists weave carbon nanotubes into a record-setting ballistic fabric

Key finding: A research team led by Jin Zhang at Peking University reports a fabric reinforced with treated single-walled carbon nanotubes (tl-SWNTs) and aramid polymers that is about three times stronger than Kevlar, measures just 1.8 mm thick, and absorbed 706.1 MJ/m3 in ballistic tests — a value the authors say doubles the previous record for macroscopic polymer fibers. The work appears in the journal Matter.

Why this matters

Kevlar, invented in the 1960s, became a benchmark for lightweight, high-strength ballistic protection and has been credited with saving thousands of lives, including an estimated 3,000 police officers, according to the U.S. National Institute of Justice. Researchers continue searching for next-generation materials that offer higher strength, greater energy absorption and reduced weight — qualities that could improve body armor, vehicle protection and aircraft safety.

How the material works

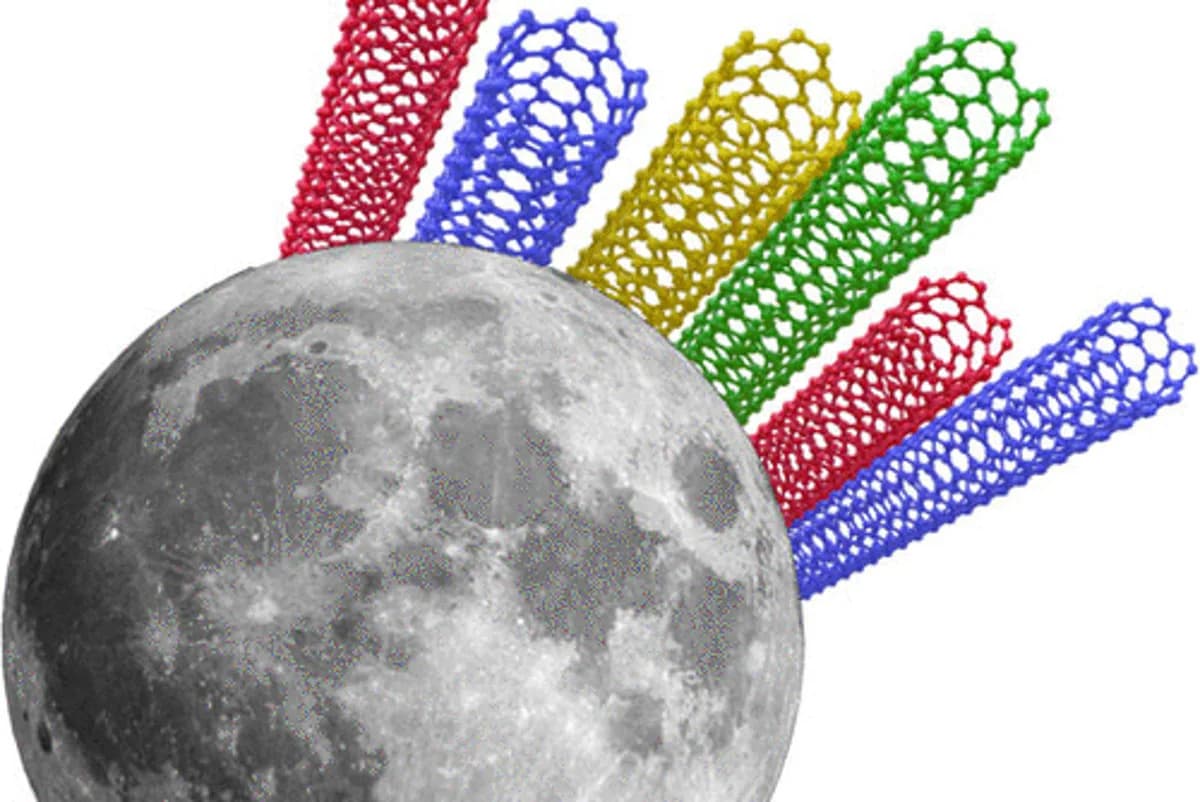

The team combined aramid polymer chains (the same class of polymers used in Kevlar) with treated long single-walled carbon nanotubes. By making the aramid chains more flexible and then stretching the composite, the researchers achieved nanoscale alignment: polymer chains and nanotubes lie parallel and interlock. That ordered structure prevents slippage between components under extreme impact and helps the material absorb much more energy without catastrophic failure.

"Ultra-high dynamic strength and toughness are crucial for fibrous materials in impact-protective applications... Our new fibre significantly surpasses all reported macroscopic high-performance polymer fibers," Jin Zhang told New Scientist.

Performance and caveats

In ballistic tests the composite absorbed 706.1 MJ/m3, which the researchers state doubles the prior record for macroscopic polymer fibers. They also report dynamic strength and toughness metrics that, in their view, exceed previously reported high-performance polymer fibers. However, the paper and accompanying reporting focus on laboratory-scale demonstration. Important questions remain about manufacturing scale-up, cost, long-term durability, environmental stability, and performance in full, multi-layer body armor systems under varied real-world conditions.

Context and next steps

This work joins other contenders for next-generation ballistic materials — from molecular “chainmail” concepts and ultra-high-molecular-weight polyethylene (e.g., Dyneema) to synthetic spider silk — but its combination of extreme tensile performance, thin profile (1.8 mm) and record energy absorption makes it notable. The authors argue their approach offers a feasible route to translate the intrinsic mechanical advantages of polymer chains to macroscopic, usable fibers, but further development and independent validation will be needed before deployment in protective gear.

Bottom line: Carbon-nanotube-reinforced aramid fibers show promising, record-level lab performance and could point toward lighter, tougher ballistic materials — but practical hurdles remain before they can replace established armors like Kevlar.

Help us improve.