Researchers at ETH Zurich used the G‑FLight system to 3D‑print muscle tissue during short periods of weightlessness on parabolic flights. Microgravity reduces the mechanical strain that gravity places on bioinks, enabling more accurate formation of muscle fibers. This advance is an early but important step toward producing complex, vascularized tissues and potentially transplantable organs, with implications for both Earth‑based medicine and astronaut health.

ETH Zurich 3D‑Prints Muscle Tissue in Microgravity with G‑FLight — A Step Toward Space‑Made Organs

ETH Zurich 3D‑prints muscle tissue in microgravity using G‑FLight

Researchers at ETH Zurich have demonstrated that muscle tissue can be 3D‑printed under simulated microgravity conditions, using a biofabrication platform called G‑FLight (Gravity‑independent Filamented Light). The team used short periods of weightlessness during parabolic flights to reduce the effect of gravity on bioinks and to better reproduce the delicate structure of human muscle fibers.

Why microgravity?

On Earth, gravity exerts stress on bioinks and fragile printed structures, making it difficult to form aligned, functional muscle fibers and other vascularized tissues. According to a press release from ETH Zurich's Department of Health Sciences and Technology, the microgravity environment removes or greatly reduces those mechanical stresses, allowing researchers to build finer, more accurate tissue architectures.

How the experiment worked

The team printed muscle constructs on parabolic flights — brief intervals of weightlessness created by the aircraft's maneuver — using the G‑FLight system. This gravity‑independent approach layers bioink with precise light‑based filamentation, enabling controlled deposition in conditions that better mimic the cellular environment of the human body.

What this means

This work represents a promising step toward the long‑term goal of manufacturing transplantable human organs. If researchers can reliably produce complex, vascularized tissues in microgravity, it could accelerate development of organs for transplantation and expand experimental options for medical research.

Note: these results are an important advance but not an immediate path to full, transplantable organs. Additional research is needed to scale, vascularize, and mature printed tissues before clinical use.

Broader context and potential applications

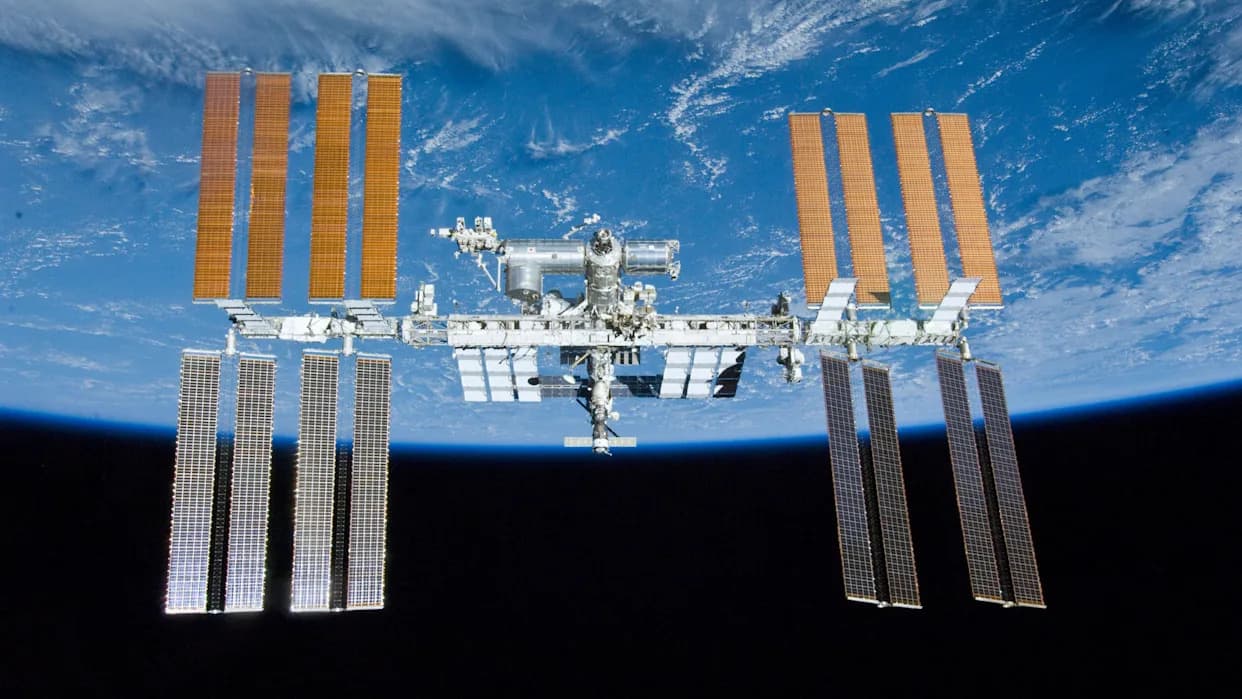

Printing tissue in microgravity is an active and expanding field. Examples of related research include efforts to manufacture artificial retinas in space, 3D‑printing vascularized liver constructs, and previous successes with bioprinted bladders and a transplanted 3D‑printed windpipe on Earth. The ability to print and test muscle tissue in microgravity could also inform countermeasures for astronauts, since prolonged exposure to microgravity causes significant muscle loss during long missions.

Researchers and space agencies are exploring plans to send more complex bioprinted constructs — including cardiac tissue prototypes — to orbit to study how long‑term space conditions affect tissue development and implant behavior. While promising, these initiatives remain research steps toward eventual clinical and space‑medicine applications.

Bottom line: ETH Zurich’s G‑FLight experiments show that microgravity can offer tangible advantages for biofabrication. The study advances the science of 3D‑printing human tissues and strengthens the case for conducting some stages of organ engineering in space or simulated weightless environments.

Help us improve.